Housing: The housing of the PVE Series pump is made from high-strength cast iron or aluminum alloy, depending on the model.

The housing provides a sturdy and rigid structure to support the internal components and ensure reliable operation even under demanding conditions.

Cylinder Block: The cylinder block is the heart of the hydraulic pump and is responsible for generating the fluid flow. It consists of a series of precisely machined pistons and cylinders that create pressure differentials to move the hydraulic fluid. The cylinder block in the PVE Series pumps is designed for high efficiency and low friction, resulting in reduced energy consumption.

Piston Assembly: The piston assembly comprises a set of pistons that reciprocate within the cylinder block. These pistons are designed to provide smooth and efficient fluid displacement, ensuring precise control over the hydraulic system. The PVE Series pumps offer various piston sizes to accommodate different flow and pressure requirements.

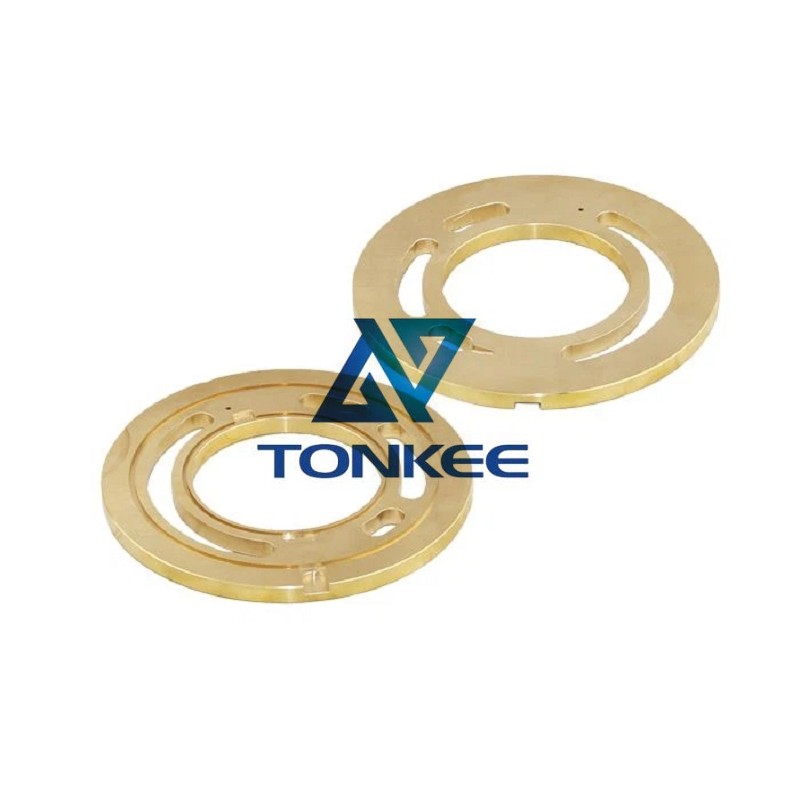

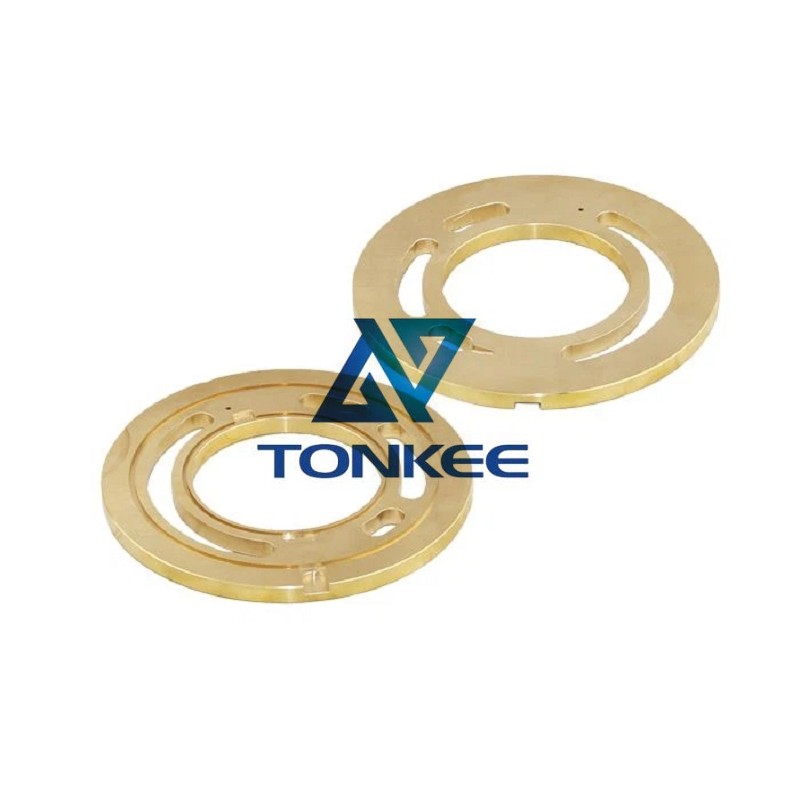

Valve Plate: The valve plate is an essential component that controls the flow of hydraulic fluid within the pump. It contains a series of valves that regulate the inlet and outlet ports, allowing the fluid to enter and exit the cylinder block at the right time. The valve plate in the PVE Series pumps is engineered for optimal performance and minimal pressure losses.

Drive Shaft: The drive shaft connects the pump to the power source, such as an electric motor or an engine. It transmits the rotational motion from the power source to the cylinder block, enabling the fluid displacement. The drive shaft in the PVE Series pumps is designed to handle high torque loads and provide reliable power transmission.

Bearings: The PVE Series pumps incorporate high-quality bearings to support the rotating components and minimize friction losses.

These bearings are precision-engineered to provide long service life and ensure smooth operation even under heavy loads. The use of high-performance bearings contributes to the overall efficiency and reliability of the pump.

Seals and Gaskets: Seals and gaskets are critical for preventing hydraulic fluid leakage and maintaining system integrity. The PVE Series pumps utilize advanced sealing technology to ensure effective sealing between the rotating and stationary parts. These seals and gaskets are made from durable materials that can withstand high pressures and temperature variations.

Control Options: The Eaton Vickers PVE Series pumps offer various control options to suit different application requirements. These options include pressure compensator, load-sensing, and flow control compensator. The control mechanisms enable precise control over the pump's output, allowing for efficient operation and energy savings.

English

English português

português Русский язык

Русский язык