The TB45 Retainer Plate is constructed using durable and robust materials to withstand the demanding conditions of hydraulic systems.

Typically made from high-strength steel or other suitable alloys, this plate offers excellent resistance to wear, corrosion, and mechanical stress. Its sturdy construction ensures the reliability and stability of the hydraulic pump assembly, even under heavy loads and extreme operating conditions.

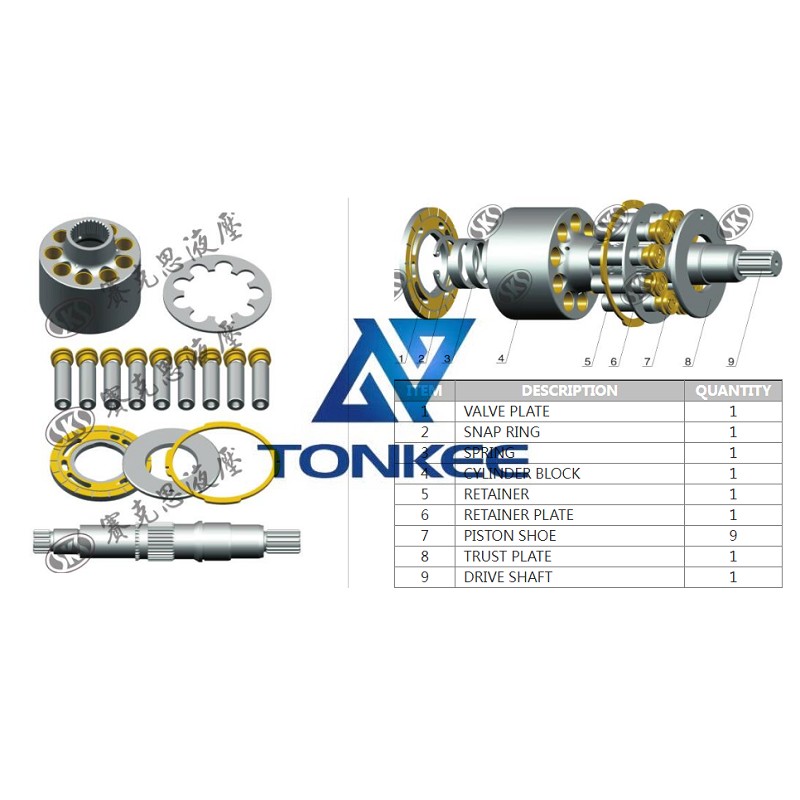

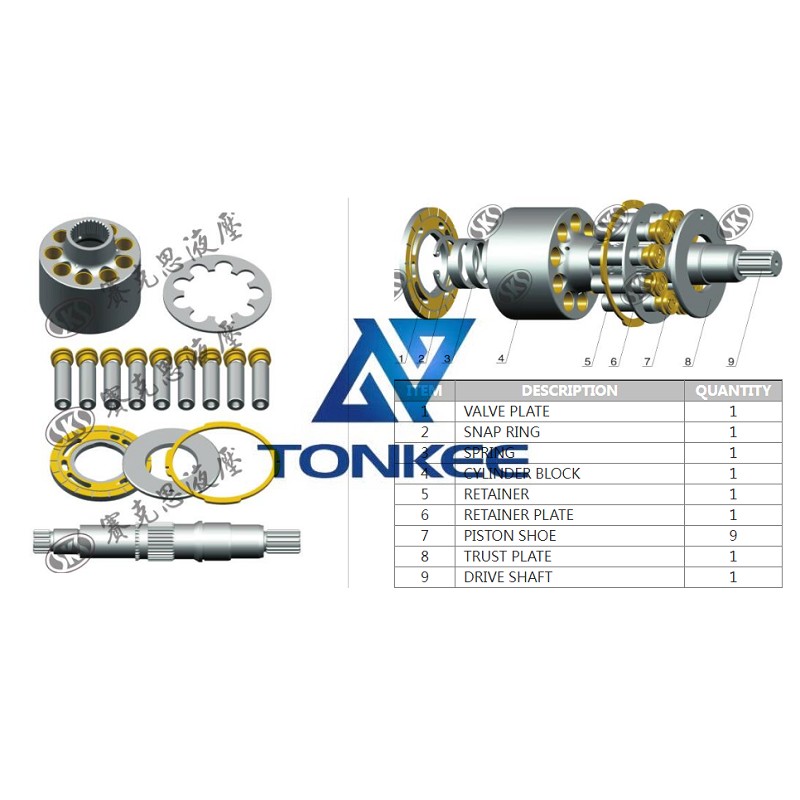

One of the primary functions of the TB45 Retainer Plate is to securely hold the hydraulic pump's internal components in place. It acts as a mounting base for critical elements such as the piston, cylinder, valve, and other associated parts. By providing a stable platform, the retainer plate prevents unwanted movement or misalignment of these components, ensuring optimal performance and efficiency of the hydraulic pump.

In addition to its mounting function, the TB45 Retainer Plate also aids in distributing the load evenly across the pump assembly. Hydraulic systems generate substantial forces and pressures, and the retainer plate helps to distribute these forces effectively, minimizing stress concentration points. This distribution of forces enhances the overall durability and longevity of the hydraulic pump, reducing the risk of premature failure or component damage.

The retainer plate is designed with precision to accommodate the specific dimensions and configurations of the hydraulic pump it is intended for. Partsdic® ensures that the TB45 Retainer Plate is manufactured to meet or exceed OEM (Original Equipment Manufacturer) specifications, guaranteeing compatibility and seamless integration into various pump models. It undergoes rigorous quality control measures to ensure dimensional accuracy, surface finish, and overall performance.

Installation of the TB45 Retainer Plate is a straightforward process, typically involving securing it to the pump housing using appropriate fasteners or bolts.

The plate's design incorporates pre-drilled holes and other features to facilitate easy installation and alignment with other pump components. It is crucial to follow the manufacturer's guidelines and specifications during installation to ensure proper fitment and alignment.

Regular inspection and maintenance of the TB45 Retainer Plate are essential for optimal pump performance. Periodic checks should be carried out to assess its condition, looking for signs of wear, deformation, or damage. If any issues are detected, immediate replacement with a genuine Partsdic® TB45 Retainer Plate is recommended to maintain the pump's reliability and prevent potential failures.

English

English português

português Русский язык

Русский язык