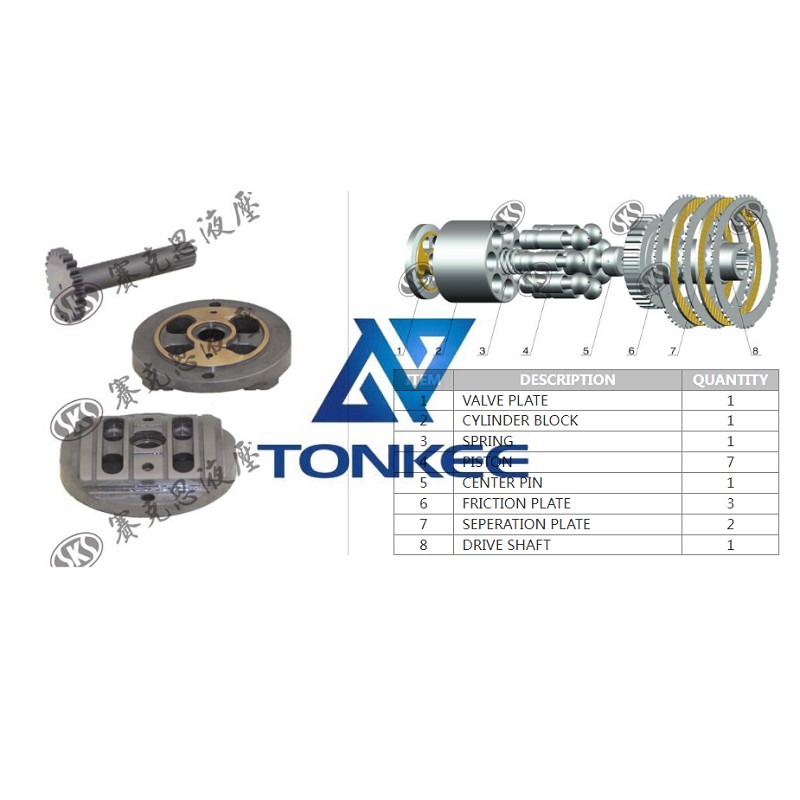

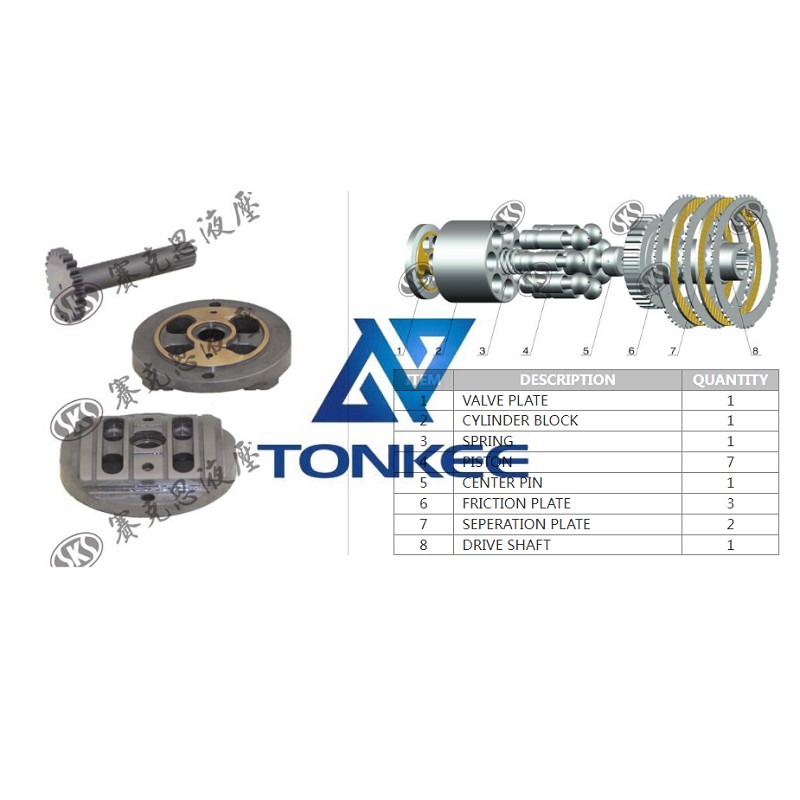

The valve plate serves a crucial function in hydraulic pumps by regulating the flow of hydraulic fluid within the system.

It consists of a flat metal plate with precision-engineered channels and ports that control the movement of the pressurized fluid. The HMGC16 valve plate is meticulously designed to ensure optimal hydraulic performance and efficiency.

One of the key features of the HMGC16 valve plate is its exceptional construction quality. It is crafted from high-grade materials, such as hardened steel or other suitable alloys, to withstand the high pressures and forces encountered in hydraulic systems. This ensures longevity and minimizes the risk of failure or damage during operation, even under demanding conditions.

The HMGC16 valve plate incorporates advanced engineering techniques to achieve precise flow control. Its intricate channel design and port arrangement allow for accurate modulation of the fluid flow, ensuring smooth and efficient operation of the hydraulic pump. This precision enhances overall system performance, responsiveness, and energy efficiency.

Tonkee® pays great attention to the manufacturing tolerances of the HMGC16 valve plate.

Through strict quality control measures and rigorous testing, the valve plate maintains tight dimensional tolerances, ensuring proper fitment and compatibility with the hydraulic pump. This level of precision ensures optimal sealing and eliminates leakage, preventing potential performance issues and hydraulic system malfunctions.

The HMGC16 valve plate is designed to be interchangeable with compatible hydraulic pump models, providing ease of replacement and maintenance. This interchangeability allows for convenient servicing and reduces downtime in case of component failure or wear.

Tonkee® understands the importance of meeting industry standards and specifications. The HMGC16 valve plate complies with stringent quality and performance standards, ensuring its reliability and suitability for various hydraulic applications. It undergoes rigorous testing procedures, including pressure and endurance tests, to validate its performance and durability.

English

English português

português Русский язык

Русский язык